This is my first post . So if I'm out turn here, please be gentle.

Just got a DIY CNC machine running, and wanted to make some simple spur gears using FreeCAD. Googling led me to this thread, which thanks to the efforts of neondata & quirxi, was a major find for what I was after.

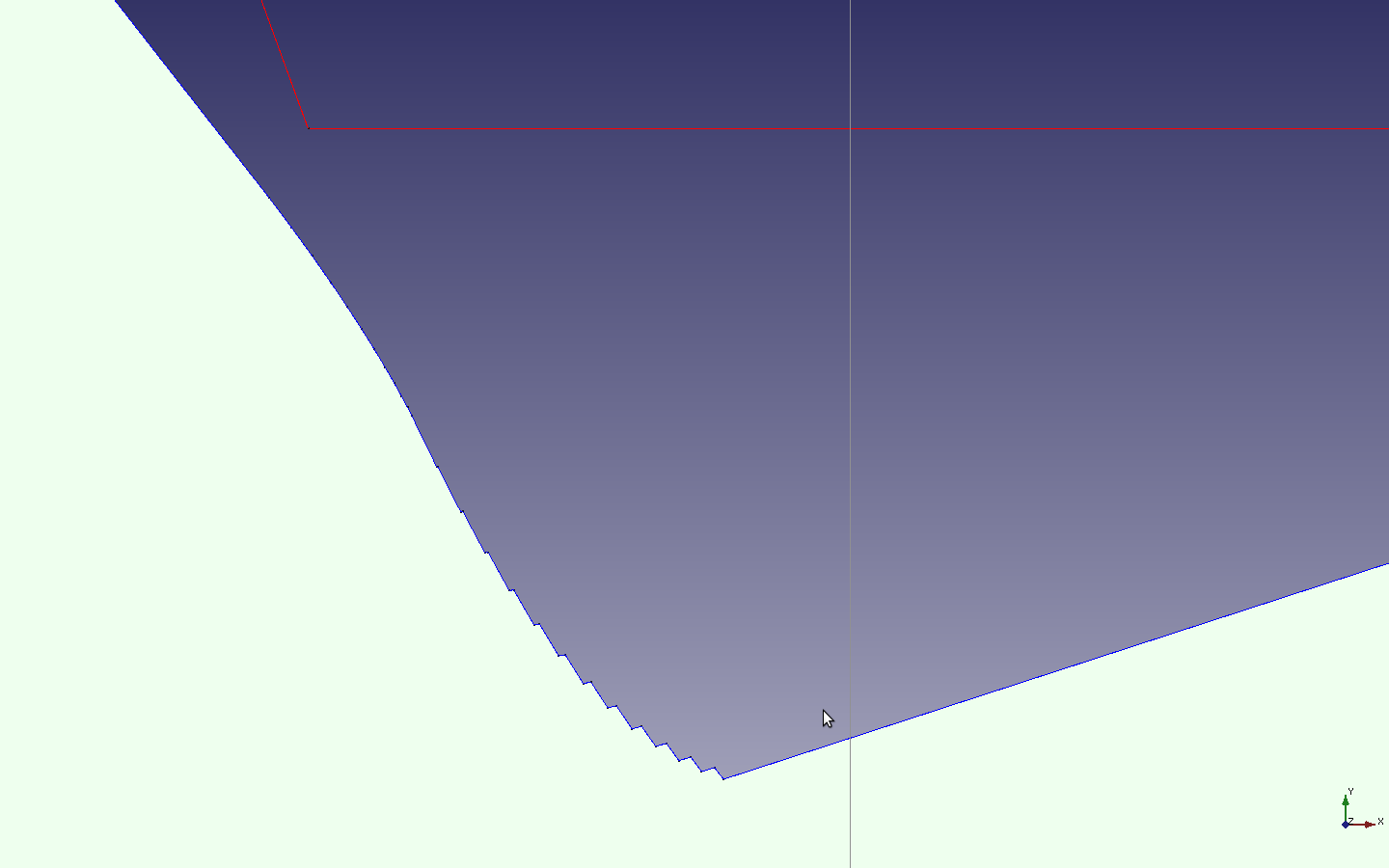

I used that code to cut several [wood] gears, and found that while they rolled well against one another, there was considerable backlash. Because everything was new to me (and I mean everything) it took a while to sort out where the "free play" was coming from. Turns out that while the Sept 7th code correctly calculated the circular tooth tickness and mirror angle, it wasn't compensating for the angular distance traveled by the involute from the base circle to the pitch circle. With this small change, the CNC machine is now cutting gears that both mesh & roll well. So again, I want to say thanks to all who made this thread possible.

And in the spirit of sharing, here's quirxi & neondata's code with changes to address the issue described above.

Code: Select all

# Copyright 2013 Arno Wilhelm <aDOTwEDquirxiDOTnet>

#

#This program is free software: you can redistribute it and/or modify

#it under the terms of the GNU General Public License as published by

#the Free Software Foundation, either version 3 of the License, or

#(at your option) any later version.

#This program is distributed in the hope that it will be useful,

#but WITHOUT ANY WARRANTY; without even the implied warranty of

#MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

#GNU General Public License for more details.

#You should have received a copy of the GNU General Public License

#along with this program. If not, see <http://www.gnu.org/licenses/>.

import Part

from FreeCAD import Base

from math import *

import FreeCAD as App, FreeCADGui as Gui, Part, Draft, math, MeshPart, Mesh

from PyQt4 import QtGui,QtCore

# default [initial] gear attributes [parameters]

N =32 # NumberTeeth

alfa = 20.0 # PressureAngle

GearHeight = 5.0 #e.g. material thickness)

#outerDiameter = (float(NumberTeeth)+2.0) * Module

outerDiameter = 60

Module = float(outerDiameter)/(float(N)+2.0)

p = math.pi * Module #circular pitch

#Module=10.0 #The length in mm of the pitch circle diameter per tooth.

ShaftDia = 6.25 #Diameter of center hole (used for mounting shaft)

# get the angle between (0,0,0) and two points where the involute

# intersects at a given radius

def getInvoluteIntersectAngle(innerRadius, outerRadius):

innerRadius, outerRadius = float(innerRadius), float(outerRadius)

return (sqrt(outerRadius**2 - innerRadius**2) / (innerRadius)) - (acos(innerRadius / outerRadius))

# calculate Point on Circle in x-y plane with given radius and angle:

# |

# alpha | y

# -------------|

# x

# sin(alpha) = y / radius => y = sin(alpha)*radius

# cos(alpha) = x / radius => x = cos(alpha)*radius

def getPointOnCircle(radius, angle):

x = radius * cos(radians(angle))

y = radius * sin(radians(angle))

return App.Vector( x, y, 0.0)

class MyGear:

def __init__(self, obj):

''' Add the properties: NumberTeeth, Module, PressureAngle, GearHeight, CenterRadius, Verbose (see Property View)'''

obj.addProperty("App::PropertyInteger","NumberTeeth","Gear","Number of teeth").NumberTeeth= 0 #will be defined later through User Input screen

obj.addProperty("App::PropertyFloat","Module","Gear","The length in mm of the pitch circle diameter per tooth.").Module= Module

obj.addProperty("App::PropertyAngle","PressureAngle","Gear","Pressure Angle (common values: 14.5, 20, 25 degrees)").PressureAngle= 0

obj.addProperty("App::PropertyLength","GearHeight","Gear","Height of gear (=material thickness)").GearHeight= 0

obj.addProperty("App::PropertyLength","CenterRadius","Gear","Radius of center hole (used for mounting shaft)").CenterRadius= 0

obj.addProperty("App::PropertyInteger","LevelOfDetail","Gear","Level of detail of involute. The higher the number the more detail but calculation time increases.").LevelOfDetail=10

obj.addProperty("App::PropertyBool","Verbose","Gear","Verbose mode shows data in output window.").Verbose=True

obj.addProperty("App::PropertyBool","AutoReCalc","Gear","When 'True' View will Update /w Porperty Value Changes").AutoReCalc=False

obj.Proxy = self

def onChanged(self, fp, prop):

if prop == "NumberTeeth" or prop == "Module" or prop == "PressureAngle" or prop == "GearHeight" or prop == "CenterRadius" or prop == "LevelOfDetail" or prop == "Verbose": #if one of these is changed

AutoReCalc = fp.AutoReCalc

if fp.AutoReCalc:

self.execute(fp)

# main part of script

def execute(self, fp):

numberTeeth = fp.NumberTeeth

module = fp.Module

pressureAngle = fp.PressureAngle

gearHeight = fp.GearHeight

centerRadius = fp.CenterRadius

nrPoints2Calculate = fp.LevelOfDetail

verbose = fp.Verbose

# sometimes position changes (why?): remeber value and reassign at end of method:

#print "-> Name: %s" % fp.Name

#print "-> Placement: %s" % fp.Placement

#print "-> Placement.Base: %s" % fp.Placement.Base

#print "-> Placement.Rotation: %s" % fp.Placement.Rotation

placementBase = fp.Placement.Base

placementRotation = fp.Placement.Rotation

if numberTeeth <= 5:

raise Exception("Error: Number of teeth must not be <= 5 !")

if module < 0.1 or module > 70:

raise Exception("Error: Module out of range! Must be >= 0.1 and <= 70.")

if gearHeight <= 0:

raise Exception("Error: Height of gear must not be <= zero !")

if centerRadius < 0:

raise Exception("Error: Radius of center must not be negativ !")

if nrPoints2Calculate < 3:

raise Exception("Error: Level of detail must not be < 3 !")

## Outside Diameter

# The outside diameter of the gear.

# OD = (N + 2) x MOD

outerDiameter = (numberTeeth+2.0) * module

outerRadius = outerDiameter / 2

## Pitch Circle Diameter

# The diameter of the pitch circle.

# PCD = N x MOD

pitchDiameter = float(numberTeeth) * module

pitchRadius = pitchDiameter / 2

## Base diameter

# The base diameter from where tooth generation starts

baseDiameter = pitchDiameter * cos(radians(pressureAngle))

baseRadius = baseDiameter / 2

## Circular Pitch

# The distance between adjacent teeth measured along the arc at the pitch circle diameter.

# CP = pi x MOD

circularPitch = pi * module

## Circular Tooth Thickness

# The width of a tooth measured along the arc at the pitch circle diameter.

# CTT = CP / 2

circularToothTickness = circularPitch / 2

## Addendum

# The height of the tooth above the pitch circle diameter.

# A = MOD

addendum = module

## Whole Depth

# The total depth of the space between adjacent teeth.

if module >= 1 and module <=70: #DIN 3960 (1987) 1 <= m <= 70 : hp = 2.25 *m

wholeDepth = 2.25 * module

elif module > 0.6 and module < 1: #DIN 5840 (1984) 0.6 < m <= 1 : hp = 2.45 * m

wholeDepth = 2.45 * module

elif module >= 0.1 and module <= 0.6: #DIN 5840 (1984) 0.1 <= m <= 0.6 : hp = 2.6 * m

wholeDepth = 2.6 * module

# Old version:

# if module < 1.25: # Finer than 1.25 MOD: H = 2.4 x MOD

# wholeDepth = 2.4 * module

# else: # 1.25 MOD and coarser: H = 2.25 x MOD

# wholeDepth = 2.25 * module

## Dedendum

# The depth of the tooth below the pitch circle diameter.

# D = H - A

dedendum = wholeDepth - addendum

## Root Diameter

# Diameter of bottom of tooth spaces. Comprises clearence

rootDiameter = pitchDiameter - 2*dedendum

rootRadius = rootDiameter / 2

if centerRadius > rootRadius + 1:

raise Exception("Error: Diameter of hole in center may not be greater then gear itself!")

if verbose:

print "\nNumber Teeth: %s" % numberTeeth

print "Module: %s" % module

print "Pressure Angle: %s" % pressureAngle

print "Diametral Pitch: %s" % (25.4 / module)

print "Circular Pitch: %s" % circularPitch

print "Circular Tooth Thickness: %s" % circularToothTickness

print "Whole Depth: %s" % wholeDepth

print "Addendum: %s" % addendum

print "Dedendum: %s" % dedendum

print "Outer Diameter: %s" % outerDiameter

print "Pitch Diameter: %s" % pitchDiameter

print "Base Diameter: %s" % baseDiameter

print "Root Diameter: %s" % rootDiameter

print "Outer Radius: %s" % outerRadius

print "Pitch Radius: %s" % pitchRadius

print "Base Radius: %s" % baseRadius

print "Root Radius: %s" % rootRadius

# draw outer circle

outerCircle = Part.Circle()

outerCircle.Radius = outerRadius

outerCircleObj = fp.Document.addObject("Part::Feature", "Outer Circle")

outerCircleObj.ViewObject.LineWidth = 1.0

outerCircleObj.ViewObject.LineColor = (0.00,0.00,1.00)

outerCircleObj.Shape = outerCircle.toShape()

outerCircleObj.ViewObject.hide()

# draw pitch circle

pitchCircle = Part.Circle()

pitchCircle.Radius = pitchRadius

pitchCircleObj = fp.Document.addObject("Part::Feature", "Pitch Circle")

pitchCircleObj.ViewObject.LineWidth = 1.0

pitchCircleObj.ViewObject.LineColor = (0.00,0.00,1.00)

pitchCircleObj.Shape = pitchCircle.toShape()

pitchCircleObj.ViewObject.hide()

# draw base circle

baseCircle = Part.Circle()

baseCircle.Radius = baseRadius

baseCircleObj = fp.Document.addObject("Part::Feature", "Base Circle")

baseCircleObj.ViewObject.LineWidth = 1.0

baseCircleObj.ViewObject.LineColor = (0.00,0.00,1.00)

baseCircleObj.Shape = baseCircle.toShape()

baseCircleObj.ViewObject.hide()

# draw root circle

rootCircle = Part.Circle()

rootCircle.Radius = rootRadius

rootCircleObj = fp.Document.addObject("Part::Feature", "Root Circle")

rootCircleObj.ViewObject.LineWidth = 1.0

rootCircleObj.ViewObject.LineColor = (0.00,0.00,1.00)

rootCircleObj.Shape = rootCircle.toShape()

rootCircleObj.ViewObject.hide()

# draw crosshair

verticalCross=Part.Line()

verticalCross.StartPoint=(0.0,-(outerRadius+10),0.0)

verticalCross.EndPoint=(0.0,(outerRadius+10),0.0)

verticalCrossObj=fp.Document.addObject("Part::Feature","Vertical Cross")

verticalCrossObj.ViewObject.LineWidth = 0.5

verticalCrossObj.ViewObject.LineColor = (0.57,0.57,0.57)

verticalCrossObj.Shape = verticalCross.toShape()

verticalCrossObj.ViewObject.hide()

horizontalCross=Part.Line()

horizontalCross.StartPoint=(-(outerRadius+10),0.0, 0.0,)

horizontalCross.EndPoint=((outerRadius+10),0.0, 0.0,)

horizontalCrossObj=fp.Document.addObject("Part::Feature","Horizontal Cross")

horizontalCrossObj.ViewObject.LineWidth = 0.5

horizontalCrossObj.ViewObject.LineColor = (0.57,0.57,0.57)

horizontalCrossObj.Shape = horizontalCross.toShape()

horizontalCrossObj.ViewObject.hide()

# calculate angle of involute curve from base circle to outer circle

toothFlankAngle = (sqrt( outerRadius*outerRadius - baseRadius*baseRadius )) / baseRadius

if verbose: print "Angel of Tooth Flank: %s" % toothFlankAngle

# divide the toothFlankAngle trough the number of points that should be

# calculated along the involute curve in order to construct this curve.

# The higher the number of points the smaller the single angle and the more

# detailed the resulting curve

singleAngle = toothFlankAngle / float(nrPoints2Calculate) #measured in radians

# calculate x and y coordinate for each point along the involute curve where the

# angle = [0 : nrPoints2Calculate]*singleAngle <= toothFlankAngle

# make list of points

pointList = list()

lineList = list()

if verbose: print "Base Circle Circumfence: %s" % (2*baseRadius*pi)

for step in range(0, nrPoints2Calculate+1):

# angle for current point

angle = singleAngle * step

# length from tangent point to involute point

s = baseRadius*angle

# calculate point on base circle where involute is tangent to the circle

xtCoord = baseRadius * cos(angle)

ytCoord = baseRadius * sin(angle)

# calculate point on involute curve

xiCoord = xtCoord + s * sin(angle)

yiCoord = ytCoord - s * cos(angle)

pointList.append( App.Vector( float(xiCoord), float(yiCoord), 0.0 ) )

if len(pointList) > 1:

line = Part.Line(pointList[-2], pointList[-1])

lineList.append(line.toShape())

involuteWire = Part.Wire(lineList)

# draw line from end of involute to root cirlce.

# This line goes from endpoint of involute (on base circle) to root circle

# in the direction towards the center of the gear and provides clearence.

# either: rootLine = Part.Line(pointList[0], getPointOnCircle(rootRadius, 0) )

# or ma is simple because endpoint of involute lies on x-axis :O :

rootLine = Part.Line(App.Vector(rootRadius, 0), App.Vector(baseRadius, 0) )

rootLineWire=Part.Wire(rootLine.toShape().Edges)

involute = Part.Wire([rootLineWire, involuteWire])

# calculate mirror line for single tooth flank

# mirror line goes trough (0,0,0) and the point on the pitch circle where

# lenght along pitch circle = circularToothTickness/2

# calculate angle:

# Attention: since the involute starts at the base circle at angle 0 but

# the angle of mirrorline is calculated from point were involute intersects

# pitch circle we have to add this angle to the mirror angle.

# Die Laenge b eines Kreisbogens mit dem Mittelpunktswinkel alpha im Winkelmass

# und dem Radius r lewsst sich durch folgende Formel berechnen:

# b = pi * r (alpha\180) => alpha = (b * 180) / (pi * r)

# mirrorAngle = ( (circularToothTickness/2.0) * 180.0) / ( pi * pitchRadius )

# OR MUCH EASIER :): mirrorAngle = (360.0 / numberTeeth) / 4.0

toothAngle = 360.0 / numberTeeth

baseToPitchAngle = getInvoluteIntersectAngle( baseRadius, pitchRadius )

# my way for deriving baseToPitchAngle

#First, for the given pressure angle, find the tangental length of string needed to span the

#distance from the base circle to the pitch circle

StrLen = sqrt(pitchRadius**2- (pitchRadius*cos(radians(pressureAngle)))**2)

#print "String Lenght = %s" %StrLen

#Cicumference formula; C = 2*Pi*r; or Distance along a circle is d = radius*angle(in radians)

#=> angle = d/radius; So in this case:

baseToPitchAngle = degrees(StrLen/baseRadius)- pressureAngle

# TODO: is this baseToPitchAngle in degree or radians ?! Is calculation right??

#mirrorAngle = (toothAngle/4.0) + degrees(baseToPitchAngle)

mirrorAngle = toothAngle/4.0

#mirrorAngle = (toothAngle/4.0) + baseToPitchAngle

# print "Method 1 mirrorAngle: %s" % mirrorAngle

# mirrorAngle = ( (circularToothTickness/2.0) * 180.0) / ( pi * pitchRadius )

# print "Method 2 mirrorAngle: %s" % mirrorAngle

MymirrorPoint = getPointOnCircle(outerRadius, mirrorAngle+(2*baseToPitchAngle))

mirrorPoint = getPointOnCircle(outerRadius, mirrorAngle)

if verbose:

MrAnglCalcTT = (pitchRadius)*radians(2*mirrorAngle)

print "Angle single tooth occupies: %s Degs" % toothAngle

print "Angle between involute on base circle and involute on pitch circle: %s ?!" % baseToPitchAngle

print "Mirror angle: %s" % mirrorAngle

print "Mirror point: %s" % mirrorPoint

print "Tooth Thickness based on Mirror angle : %s" % MrAnglCalcTT

offsetAngle = baseToPitchAngle

MAxCoord = outerRadius * cos(radians(mirrorAngle+offsetAngle))

MAyCoord = outerRadius * sin(radians(mirrorAngle+offsetAngle))

Mirrorangle=Part.Line()

Mirrorangle.StartPoint=(0.0,0.0, 0.0,)

Mirrorangle.EndPoint=(float(MAxCoord), float(MAyCoord), 0.0,)

MirrorangleObj=fp.Document.addObject("Part::Feature","Mirror Angle")

MirrorangleObj.ViewObject.LineWidth = 0.5

MirrorangleObj.ViewObject.LineColor = (0.57,0.57,0.57)

MirrorangleObj.Shape = Mirrorangle.toShape()

MirrorangleObj.ViewObject.hide()

StrtPoint = getPointOnCircle(outerRadius, offsetAngle)

CntrPoint = getPointOnCircle(0, 0)

EndPoint = getPointOnCircle(outerRadius, 2*(mirrorAngle)+offsetAngle)

CTTLine = Part.makePolygon([StrtPoint,CntrPoint, EndPoint])

CTTLineObj=fp.Document.addObject("Part::Feature","Circular Tooth Thickness")

CTTLineObj.ViewObject.LineWidth = 0.5

CTTLineObj.ViewObject.LineColor = (0.57,0.57,0.57)

CTTLineObj.Shape = CTTLine

CTTLineObj.ViewObject.hide()

# mirror involute around line in middle of tooth (=mirrorLine)

# calculate the transform matrix for reflection around arbitrary line through (0,0,0)

# see: http://www.scibuff.com/2009/06/22/reflection-matrix/

# see: http://answers.yahoo.com/question/index?qid=20110628095842AARdMwL

# see: http://www.geom.uiuc.edu/docs/reference/CRC-formulas/node9.html

# oans = float(cos(2*radians(mirrorAngle)))

# zwoa = float(sin(2*radians(mirrorAngle)))

# drai = float(sin(2*radians(mirrorAngle)))

# via = float(-(cos(2*radians(mirrorAngle))))

# use my mirrorAngle+(2*baseToPitchAngle to work out the new mirror matrix

oans = float(cos(2*radians(mirrorAngle+(1*baseToPitchAngle))))

zwoa = float(sin(2*radians(mirrorAngle+(1*baseToPitchAngle))))

drai = float(sin(2*radians(mirrorAngle+(1*baseToPitchAngle))))

via = float(-(cos(2*radians(mirrorAngle+(1*baseToPitchAngle)))))

mirrorMatrix = Base.Matrix(oans,zwoa,0.0,0.0,drai,via,0.0,0.0,0.0,0.0,0.0,0.0,0.0,0.0,0.0,0.0)

if verbose: print "mirrorMatrix: %s" % mirrorMatrix

mirrorInvolute = involute.transformGeometry(mirrorMatrix)

# Since the vertexes in the mirrored involute are reversed in the list of vertices ->

# -> in order to join them successfully with the other wires we have to reverse them:

edgeList = []

for i in xrange(len(mirrorInvolute.Vertexes)-1, -1, -1):

if i < (len(mirrorInvolute.Vertexes)-1):

edge = Part.Line(mirrorInvolute.Vertexes[i+1].Point, mirrorInvolute.Vertexes[i].Point)

edgeList.append(edge.toShape())

reversedMirroredInvolute = Part.Wire(edgeList)

# draw arc between two involutes on outer circle

outerArc = Part.Arc(pointList[-1],mirrorPoint, mirrorInvolute.Edges[-1].Vertexes[-1].Point)

outerArcWire = Part.Wire( outerArc.toShape().Edges )

# draw arc between two teeth on root circle

firstPoint = reversedMirroredInvolute.Edges[-1].Vertexes[-1].Point

middlePoint = getPointOnCircle(rootRadius, ((toothAngle/4.0)*3.0))

endPoint = getPointOnCircle(rootRadius, toothAngle)

#middlePoint = getPointOnCircle(rootRadius, (((toothAngle/4.0)*3.0)+baseToPitchAngle))

#endPoint = getPointOnCircle(rootRadius, (toothAngle+baseToPitchAngle))

innerArc = Part.Arc(firstPoint, middlePoint, endPoint)

innerArcWire = Part.Wire( innerArc.toShape().Edges )

# join single wires in order to get whole tooth

wholeTooth = Part.Wire([involute, outerArcWire, reversedMirroredInvolute, innerArcWire])

# Show wholeTooth as a wire [I added this]

wholeToothObj=fp.Document.addObject("Part::Feature","Whole Tooth Wire")

wholeToothObj.ViewObject.LineWidth = 0.5

wholeToothObj.ViewObject.LineColor = (0.57,0.57,0.57)

wholeToothObj.Shape = wholeTooth

wholeToothObj.ViewObject.hide()

# MymirrorPointPart = Part.Point(MymirrorPoint)

# faceEdge = Part.makeLine(MymirrorPoint,MymirrorPoint+Base.Vector(0.0,0.0,1.0))

# MymirrorPointObj=fp.Document.addObject("Part::Feature","My MirrorPoint")

# MymirrorPointObj.ViewObject.LineWidth = 1.5

# MymirrorPointObj.ViewObject.LineColor = (0.57,0.57,0.57)

# MymirrorPointObj.Shape = faceEdge #MymirrorPointPart

# copy tooth numberTeeth times and rotate copies around circle

#if verbose:

# print "wholeTooth[0]: %s" % wholeTooth.Edges[0].Vertexes[0].Point

# print "wholeTooth[-1]: %s" % wholeTooth.Edges[-1].Vertexes[-1].Point

gearWire = wholeTooth.copy()

for step in range(1, numberTeeth):

toothWire = wholeTooth.copy()

toothWire.rotate(App.Vector(0.0,0.0,0.0), App.Vector(0.0,0.0,1.0), step*toothAngle)

#print "toothWire[0]: %s toothWire[-1]: %s" % (toothWire.Edges[0].Vertexes[0].Point, toothWire.Edges[-1].Vertexes[-1].Point)

## fuse() method had problems closing the shape !!??

# gearWire = gearWire.fuse(toothWire)

gearWire = Part.Wire([gearWire,toothWire])

#print "gearWire[0]: %s gearWire[-1]: %s" % (gearWire.Edges[0].Vertexes[0].Point , gearWire.Edges[-1].Vertexes[-1].Point)

# extrude 2D shape into 3d object

gearFace = Part.Face(gearWire)

## cut hole in center of gear for mounting shaft

if centerRadius > 0:

centerHole = Part.Circle()

centerHole.Radius = float(centerRadius)

centerHoleShape = centerHole.toShape()

centerHoleFace = Part.Face(Part.Wire(centerHoleShape.Edges))

gearFace = gearFace.cut(centerHoleFace)

gearShell = Part.Shell(gearFace.Faces)

extrudedGear = gearShell.extrude(Base.Vector(0.0,0.0,gearHeight))

fp.Shape = extrudedGear

# sometimes position changes (why?): reset positon to remembered value:

fp.Placement.Base = placementBase

fp.Placement.Rotation = placementRotation

def makeGear(paramlst):

NumberTeeth = paramlst[0]

PressureAngle = paramlst[1]

GearHeight = paramlst[2]

CenterRadius = paramlst[3]/2

LevelOfDetail = paramlst[4]

Module = paramlst[5]

doc = FreeCAD.activeDocument()

if doc == None:

doc = FreeCAD.newDocument("Gear")

gear=doc.addObject("Part::FeaturePython","Gear") #add object to document

gear.Label = "3DGearPart"

MyGear(gear)

gear.NumberTeeth = NumberTeeth

gear.PressureAngle = PressureAngle

gear.Module = Module

gear.GearHeight = GearHeight

gear.CenterRadius = CenterRadius

gear.LevelOfDetail = LevelOfDetail

gear.AutoReCalc = True

gear.ViewObject.Proxy=0

doc.recompute()

Gui.SendMsgToActiveView("ViewFit") # center gear in view ...

def proceed():

# try:

InitParam = []

InitParam = ExtractUsrInput()

makeGear(InitParam)

# except:

# print "\nExtractUsrInput Code Failed"

# hide()

def ExtractUsrInput():

# try:

N = int (l[0].text()) # Number of teeth (N)

# NumberTeeth=N

# m = float(l[1].text()) #module

p = float(l[1].text()) # Circular pitch (p)

m = p/math.pi

#outerDiameter = p

alfa = float(l[2].text()) # Pressure angle (alfa)

# PressureAngle=alfa

y = float(l[3].text()) # Tooth hight factor (y) standard value y<1 for gear drives y>1 for Gear pumps

# m = p/math.pi #standard value 0.06, 0.12, 0.25, 0.5, 1, 2, 4, 8, 16, 32, 60 (polish norm)

c = float(l[4].text())*m # Tooth clearance (c) standard value 0,1*m - 0,3*m

j = float(l[5].text())*m # Tooth lateral clearance (j) standard value 0,015 - 0,04*m

width = float(l[6].text()) #gear width; i.e. material thickness)

InvPts = int (l[7].text()) #resolution, # of interpolated points

SD = float(l[8].text()) #Shaft [i.e. Axle] Diameter

# except:

# FreeCAD.Console.PrintError("Wrong input! Only numbers allowed...\n")

h = 2*y*m+c #tooth height

d = N*m #pitch diameter

rp_sqr = d*d/4 # sqr pitch radius

df = d - h - c #root diameter #df=d-2hf where and hf=y*m+c

da = d + h - c #addendum diameter #da=d+2ha where ha=y*m

ra_sqr = da*da/4 # sqr addendum radius

db = d * math.cos(math.radians(alfa)) #base diameter for involute

#Base circle radius, first angle, second angle

# addendumCircle = MakeCircle("AddendumCircle", da/2, 0.0, 0.0) #Addendum circle

# pitchCircle = MakeCircle("PitchCircle", d/2, 0.0, 0.0) #Pitch circle

FreeCAD.Console.PrintError("\n\nNew Gear Parameters....\n\n")

FreeCAD.Console.PrintError("tooth height "+str(h) + "..\n")

FreeCAD.Console.PrintError("tooth thickness [CTT=CP/2] "+str(p/2) + "..\n")

FreeCAD.Console.PrintError("addendum diameter "+str(da)+ "..\n")

FreeCAD.Console.PrintError("pitch diameter "+str(d) + "..\n")

FreeCAD.Console.PrintError("base diameter "+str(db)+ "..\n")

FreeCAD.Console.PrintError("root diameter "+str(df)+ "..\n")

hide()

InitParam = []

InitParam.append(N)

InitParam.append(alfa)

InitParam.append(width)

InitParam.append(SD)

InitParam.append(InvPts)

InitParam.append(m)

return InitParam

def hide():

dialog.hide()

# Now Define User Input GUI

GuiSize = [200,450]

GuiTitle = "Metric Gear Params"

l = [] # Array to transfer parameters to the process

F = [["Number of teeth (N)" , "%s" % N]]

F.append(["Circular Pitch [module X Pi]" ,"%s" % p])

F.append(["Pressure angle (alfa)" , "%s" % alfa])

F.append(["Tooth height factor (y)" , "1.0"])

F.append(["Tooth clearance (c)" , "0.2"])

F.append(["Tooth lateral clearance (j)" , "0.04"])

F.append(["Gear width" , "%s" % GearHeight])

F.append(["# of points in involute" , "10"])

F.append(["Center Hole [Shaft] Diameter", "%s" %ShaftDia])

dialog = QtGui.QDialog()

dialog.resize(GuiSize[0],GuiSize[1])

dialog.setWindowTitle(GuiTitle)

la = QtGui.QVBoxLayout(dialog)

for field in range(len(F)):

la.addWidget(QtGui.QLabel(F[field][0]))

l.append( QtGui.QLineEdit(F[field][1]) )

la.addWidget(l[field])

c1 = QtGui.QCheckBox("Create as a Mesh")

la.addWidget(c1)

e1 = QtGui.QLabel("(for faster rendering)")

e1.setFont(QtGui.QFont("Times",8,True))

la.addWidget(e1)

okbox = QtGui.QDialogButtonBox(dialog)

okbox.setOrientation(QtCore.Qt.Horizontal)

okbox.setStandardButtons(QtGui.QDialogButtonBox.Cancel|QtGui.QDialogButtonBox.Ok)

la.addWidget(okbox)

QtCore.QObject.connect(okbox, QtCore.SIGNAL("accepted()"), proceed)

QtCore.QObject.connect(okbox, QtCore.SIGNAL("rejected()"), hide)

QtCore.QMetaObject.connectSlotsByName(dialog)

dialog.show()

#if __name__ == "__main__": #feature will be generated after macro execution

# confirmGearParams()

# makeGear()

PS: This is still a work in progress, so some of the parameter settings found on the setup screen actually have no effect on the rendered gear