Hello forum,

When milling a not too complex part, I am thinking it would be natural to mill the top first, then flip it over and do the bottom and then be done. For this to work, the system needs to be touched off on the flipped part somewhere, but where? At this point, the unfinished stock is exposed and there is nowhere reachable on the finished side (which is now underneath) to touch off against. In my mind, the only way would be to drill a hole through the entire stock at a known location (could be outside of the actual part or center of a hole in it, for instance). When flipping, the center of this hole would be a good origin/touch off point. This would get X and Y straight. However, FreeCAD only supports vertices as origins, not the center of a hole. What is the intended process to get the bottom aligned with the top?

Thanks,

/Chris

Align top with bottom

Forum rules

Be nice to others! Respect the FreeCAD code of conduct!

Be nice to others! Respect the FreeCAD code of conduct!

Align top with bottom

electrical engineer

Ubuntu or Mint

Mendel 3d-printer/OctoPrint

LinuxCNC

Optimum BF20L mill

Ubuntu or Mint

Mendel 3d-printer/OctoPrint

LinuxCNC

Optimum BF20L mill

Re: Align top with bottom

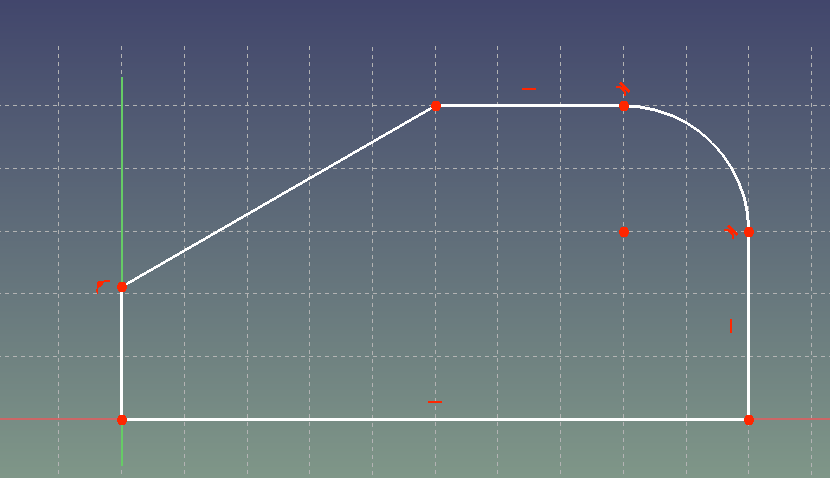

Doesn't this heavily depend on the model? If we take something like in the tutorial Creating a simple part with PartDesign. Let's say we want to mill it from both sides. In real life I would mill it from one side, then place a rectangular stop at one of the corners. Let's take the left lower corner of this:

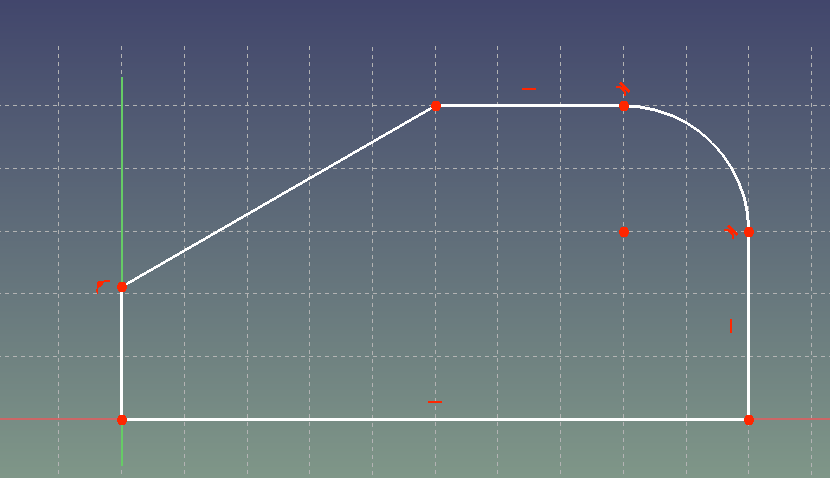

Then I would turn it so that the right lower corner matches the rectangular stop.

T reflect this in FreeCAD I would have to create a new solid for the rectangular stop. For the flipped milling I would create a new Job, turn the clone around and place it so that it meets the rectangular stop. Manipilator workbench could be helpful with the positioning.

For another object this might be completely different. I am not a milling expert, so I don't know if any standard procedures exist in real milling which should be reflected in FreeCAD, but I'm sure that drilling holes through the objects is none of them .

.

Then I would turn it so that the right lower corner matches the rectangular stop.

T reflect this in FreeCAD I would have to create a new solid for the rectangular stop. For the flipped milling I would create a new Job, turn the clone around and place it so that it meets the rectangular stop. Manipilator workbench could be helpful with the positioning.

For another object this might be completely different. I am not a milling expert, so I don't know if any standard procedures exist in real milling which should be reflected in FreeCAD, but I'm sure that drilling holes through the objects is none of them

A Sketcher Lecture with in-depth information is available in English, auf Deutsch, en français, en español.

Re: Align top with bottom

Thanks for reaching out, Chris!

I would say that this issue exists regardless of the model, but the solutions may vary. A part milled from a rectangular piece of stock is one case. Cylindrical stock is another. Some parts can be held directly in a vise or chuck, others may need a fixture. Milling the second half of an intricate part would require a sophisticated fixture to hold it. It would be possible to touch off to the fixture, since that would be a known reference to the part. I had more generic parts in mind, that could simply be held in the vice or chuck to mill the reverse side. For those, there is no intuitive reference. Touching off to the stock is no good - one piece of stock may be off by millimeters compared to the next and it may not even have a perfectly perpendicular cut anyway.

Not sure what you mean by placing a rectangular stop? Touching off to the edge of the vise and then aligning the flipped part to that edge - something like that? There is significant risk for foulup, but if done carefully, it should work. I am worried about the precision. Touching off to a known point directly on the part would feel safer.

/Chris

I would say that this issue exists regardless of the model, but the solutions may vary. A part milled from a rectangular piece of stock is one case. Cylindrical stock is another. Some parts can be held directly in a vise or chuck, others may need a fixture. Milling the second half of an intricate part would require a sophisticated fixture to hold it. It would be possible to touch off to the fixture, since that would be a known reference to the part. I had more generic parts in mind, that could simply be held in the vice or chuck to mill the reverse side. For those, there is no intuitive reference. Touching off to the stock is no good - one piece of stock may be off by millimeters compared to the next and it may not even have a perfectly perpendicular cut anyway.

Not sure what you mean by placing a rectangular stop? Touching off to the edge of the vise and then aligning the flipped part to that edge - something like that? There is significant risk for foulup, but if done carefully, it should work. I am worried about the precision. Touching off to a known point directly on the part would feel safer.

/Chris

electrical engineer

Ubuntu or Mint

Mendel 3d-printer/OctoPrint

LinuxCNC

Optimum BF20L mill

Ubuntu or Mint

Mendel 3d-printer/OctoPrint

LinuxCNC

Optimum BF20L mill

Re: Align top with bottom

Sorry for my English. I had looked it up and apparently it was wrong. A better word seems to be "angle plate", a thing shown in the first minute of e.g. this video. I would have clamped a smaller version vertically so that two rectanglular sides would have touched two sides of the angle plate.

But as I said: I am only an amateur, probably a dilettante and what you write sounds more sensible.

A Sketcher Lecture with in-depth information is available in English, auf Deutsch, en français, en español.

Re: Align top with bottom

What I often do in this situation is to make sure there are two perpendicular reference edges on the starting stock and then reference those edges for milling operations on *both* sides. The quality of the references may be good enough from the raw material or you may need to create them with a simple milling operation.

If you start with the first side randomly placed on the stock it will not be easy to find the correct reference for the second side. That is why it is necessary to carefully position the first side with respect to the reference edges.

Gene

If you start with the first side randomly placed on the stock it will not be easy to find the correct reference for the second side. That is why it is necessary to carefully position the first side with respect to the reference edges.

Gene